Tuairisgeul toraidh

Composite:Magnets tearc na Talmhainn

Meud:Gnàthaichte airson Neodymium Magnet

Còmhdach eile:Ni, Ni-Cu-Ni, Zn(Cr3+), Tin, Epoxy, Ni-AG, Ni-Au

Fulangas:+/- 0.05 airson Neodymium Magnet

Mion-fhiosrachadh Lìbhrigeadh:15 latha às deidh òrdugh air a dhearbhadh airson Magnet Neodymium

Margaidean às-mhalairt:Cruinneil

Seirbheis OEM:Tha

Cruth Eile:Arc, Cearcall, Ball, Bàr, Strick, Duilleag, Bloc airson Neo

Pasgan còmhdhail:Sea Pallet / Air Carton / Express Packaging

Tùs:Sìona

Comas riochdachaidh:10, 000, 000 PCS / Mìos

Feartan magnetach

| Ìre | Fulangas | Inntrigeadh Magnetic | Co-èigneachadh gnèitheach | Toradh lùth magnetach as àirde | Coefficient teòthachd | Teòthachd obrach as àirde | Dùmhlachd | |||||

| Br | Hcb | Hcj | (BH) as àirde | α Br | β Hcj | Tw | ρ | |||||

| T | kGs | kA/m | kOe | kA/m | kOe | KJ/m3 | MGOe | %/℃ | %/℃ | ℃ | g/cm2 | |

| N55 | ≥1.45 | ≥14.5 | 836 | 10.5 | ≥955 | ≥12 | 406-437 | 51-55 | -0.12 | -0.8 | 80 | ≥7.5 |

| N54 | ≥1.44 | ≥14.4 | 836 | 10.5 | ≥955 | ≥12 | 398-437 | 50-55 | -0.12 | -0.8 | 80 | ≥7.5 |

| N52 | 1.42-1.44 | 14.2-14.4 | 836 | 10.5 | ≥955 | ≥12 | 390-422 | 49-53 | -0.12 | -0.8 | 80 | ≥7.5 |

| N50 | 1.4-1.42 | 14-14.2 | 836 | 10.5 | ≥955 | ≥12 | 374-406 | 47-51 | -0.12 | -0.8 | 80 | ≥7.5 |

| N48 | 1.37-1.4 | 13.7-14 | 915 | 11.5 | ≥955 | ≥12 | 366-390 | 46-49 | -0.12 | -0.8 | 80 | ≥7.5 |

| N45 | 1.32-1.37 | 13.2-13.7 | 915 | 11.5 | ≥955 | ≥12 | 342-366 | 43-46 | -0.12 | -0.8 | 80 | ≥7.5 |

| 54m | ≥1.44 | ≥14.4 | 1056 | 13.3 | ≥1114 | ≥14 | 398-422 | 50-53 | -0.12 | -0.8 | 100 | ≥7.5 |

| 52m | 1.42-1.44 | 14.2-14.4 | 1056 | 13.3 | ≥1114 | ≥14 | 390-422 | 49-53 | -0.12 | -0.8 | 100 | ≥7.5 |

| 50m | 1.4-1.42 | 14-14.2 | 1034 | 13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | -0.12 | -0.8 | 100 | ≥7.5 |

| 48m | 1.37-1.4 | 13.7-14 | 1019 | 12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | -0.12 | -0.8 | 100 | ≥7.5 |

| 45m | 1.32-1.37 | 13.2-13.7 | 1008 | 12.7 | ≥1114 | ≥14 | 342-366 | 43-46 | -0.12 | -0.8 | 100 | ≥7.5 |

| 42m | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥1114 | ≥14 | 318-342 | 40-43 | -0.12 | -0.8 | 100 | ≥7.5 |

| 54h | ≥1.44 | ≥14.4 | 1056 | 13.3 | ≥1353 | ≥17 | 398-422 | 50-53 | -0.12 | -0.7 | 120 | ≥7.5 |

| 52 h | 1.42-1.44 | 14.2-14.4 | 1056 | 13.3 | ≥1353 | ≥17 | 390-422 | 49-53 | -0.12 | -0.7 | 120 | ≥7.5 |

| 50 h | 1.4-1.42 | 14-14.2 | 1034 | 13.0 | ≥1353 | ≥17 | 374-406 | 47-51 | -0.12 | -0.7 | 120 | ≥7.5 |

| 48H | 1.37-1.4 | 13.7-14 | 1019 | 12.8 | ≥1353 | ≥17 | 366-390 | 46-49 | -0.12 | -0.7 | 120 | ≥7.5 |

| 45 h | 1.32-1.37 | 13.2-13.7 | 1008 | 12.7 | ≥1353 | ≥17 | 342-366 | 43-46 | -0.12 | -0.7 | 120 | ≥7.5 |

| 42h | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥1353 | ≥17 | 318-342 | 40-43 | -0.12 | -0.7 | 120 | ≥7.5 |

| 40 h | 1.26-1.28 | 12.6-12.8 | 948 | 11.9 | ≥1353 | ≥17 | 302-326 | 38-41 | -0.12 | -0.7 | 120 | ≥7.5 |

| 52SH | 1.42-1.44 | 14.2-14.4 | 1056 | 13.3 | ≥1592 | ≥20 | 390-422 | 49-53 | -0.12 | -0.6 | 150 | ≥7.5 |

| 50SH | 1.4-1.42 | 14-14.2 | 1034 | 13.0 | ≥1592 | ≥20 | 374-406 | 47-51 | -0.12 | -0.6 | 150 | ≥7.5 |

| 48SH | 1.37-1.4 | 13.7-14 | 1019 | 12.8 | ≥1592 | ≥20 | 366-390 | 46-49 | -0.12 | -0.6 | 150 | ≥7.5 |

| 45SH | 1.32-1.37 | 13.2-13.7 | 1008 | 12.7 | ≥1592 | ≥20 | 342-366 | 43-46 | -0.12 | -0.6 | 150 | ≥7.5 |

| 42SH | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | -0.12 | -0.6 | 150 | ≥7.5 |

| 40SH | 1.26-1.28 | 12.6-12.8 | 948 | 11.9 | ≥1592 | ≥20 | 302-326 | 38-41 | -0.12 | -0.6 | 150 | ≥7.5 |

| 38SH | 1.22-1.26 | 12.2-12.6 | 925 | 11.6 | ≥1592 | ≥20 | 287-310 | 36-39 | -0.12 | -0.6 | 150 | ≥7.5 |

| 35SH | 1.17-1.22 | 11.7-12.2 | 887 | 11.1 | ≥1592 | ≥20 | 263-287 | 33-36 | -0.12 | -0.6 | 150 | ≥7.5 |

| 33SH | 1.13-1.17 | 11.3-11.7 | 857 | 10.8 | ≥1592 | ≥20 | 247-271 | 31-34 | -0.12 | -0.6 | 150 | ≥7.5 |

| 30SH | 1.08-1.13 | 10.8-11.3 | 819 | 10.3 | ≥1592 | ≥20 | 223-254 | 28-32 | -0.12 | -0.6 | 150 | ≥7.5 |

| 48UH | 1.36-1.4 | 13.6-14 | 1029 | 12.9 | ≥1990 | ≥25 | 366-390 | 46-49 | -0.12 | -0.6 | 180 | ≥7.5 |

| 45 UH | 1.32-1.37 | 13.2-13.7 | 1008 | 12.7 | ≥1990 | ≥25 | 342-366 | 43-46 | -0.12 | -0.6 | 180 | ≥7.5 |

| 42 UH | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥1990 | ≥25 | 318-342 | 40-43 | -0.12 | -0.6 | 180 | ≥7.5 |

| 40UH | 1.26-1.28 | 12.6-12.8 | 948 | 11.9 | ≥1990 | ≥25 | 302-326 | 38-41 | -0.12 | -0.6 | 180 | ≥7.5 |

| 38 UH | 1.22-1.26 | 12.2-12.6 | 925 | 11.6 | ≥1990 | ≥25 | 287-310 | 36-39 | -0.12 | -0.6 | 180 | ≥7.5 |

| 35 UH | 1.17-1.22 | 11.7-12.2 | 887 | 11.1 | ≥1990 | ≥25 | 263-287 | 33-36 | -0.12 | -0.6 | 180 | ≥7.5 |

| 33UH | 1.13-1.17 | 11.3-11.7 | 857 | 10.8 | ≥1990 | ≥25 | 247-271 | 31-34 | -0.12 | -0.6 | 180 | ≥7.5 |

| 30 UH | 1.08-1.13 | 10.8-11.3 | 819 | 10.3 | ≥1990 | ≥25 | 223-255 | 28-32 | -0.12 | -0.51 | 180 | ≥7.5 |

| 28 UH | 1.02-1.08 | 10.2-10.8 | 773 | 9.7 | ≥1990 | ≥25 | 207-231 | 26-29 | -0.12 | -0.51 | 180 | ≥7.5 |

| 42 EH | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥2388 | ≥30 | 318-342 | 40-43 | -0.12 | -0.5 | 200 | ≥7.5 |

| 40 EH | 1.25-1.28 | 12.5-12.8 | 948 | 11.9 | ≥2388 | ≥30 | 302-326 | 38-41 | -0.12 | -0.5 | 200 | ≥7.5 |

| 38 EH | 1.22-1.26 | 12.2-12.6 | 925 | 11.6 | ≥2388 | ≥30 | 287-310 | 36-39 | -0.12 | -0.5 | 200 | ≥7.5 |

| 35 EH | 1.17-1.22 | 11.7-12.2 | 887 | 11.1 | ≥2388 | ≥30 | 263-287 | 33-36 | -0.12 | -0.5 | 200 | ≥7.5 |

| 33 EH | 1.13-1.17 | 11.3-11.7 | 857 | 10.8 | ≥2388 | ≥30 | 247-271 | 31-34 | -0.12 | -0.5 | 200 | ≥7.5 |

| 30 EH | 1.08-1.13 | 10.8-11.3 | 819 | 10.3 | ≥2388 | ≥30 | 223-255 | 28-32 | -0.12 | -0.51 | 200 | ≥7.5 |

| 28 EH | 1.02-1.08 | 10.2-10.8 | 773 | 9.7 | ≥2388 | ≥30 | 207-231 | 26-29 | -0.12 | -0.51 | 200 | ≥7.5 |

| 40 Ach | 1.25-1.28 | 12.5-12.8 | 948 | 11.9 | ≥2786 | ≥35 | 302-326 | 38-41 | -0.12 | -0.51 | 220 | ≥7.5 |

| 38AiR | 1.22-1.26 | 12.2-12.6 | 925 | 11.6 | ≥2786 | ≥35 | 287-310 | 36-39 | -0.12 | -0.51 | 220 | ≥7.5 |

| 35 Ach | 1.17-1.22 | 11.7-12.2 | 887 | 11.1 | ≥2786 | ≥35 | 263-287 | 33-36 | -0.12 | -0.51 | 220 | ≥7.5 |

| 33 Ach | 1.13-1.17 | 11.3-11.7 | 857 | 10.8 | ≥2786 | ≥35 | 247-271 | 31-34 | -0.12 | -0.51 | 220 | ≥7.5 |

| 30 Ach | 1.08-1.13 | 10.8-11.3 | 819 | 10.3 | ≥2786 | ≥35 | 223-255 | 28-32 | -0.12 | -0.51 | 220 | ≥7.5 |

| 28AH | 1.02-1.08 | 10.2-10.8 | 773 | 9.7 | ≥2786 | ≥35 | 199-231 | 25-29 | -0.12 | -0.51 | 220 | ≥7.5 |

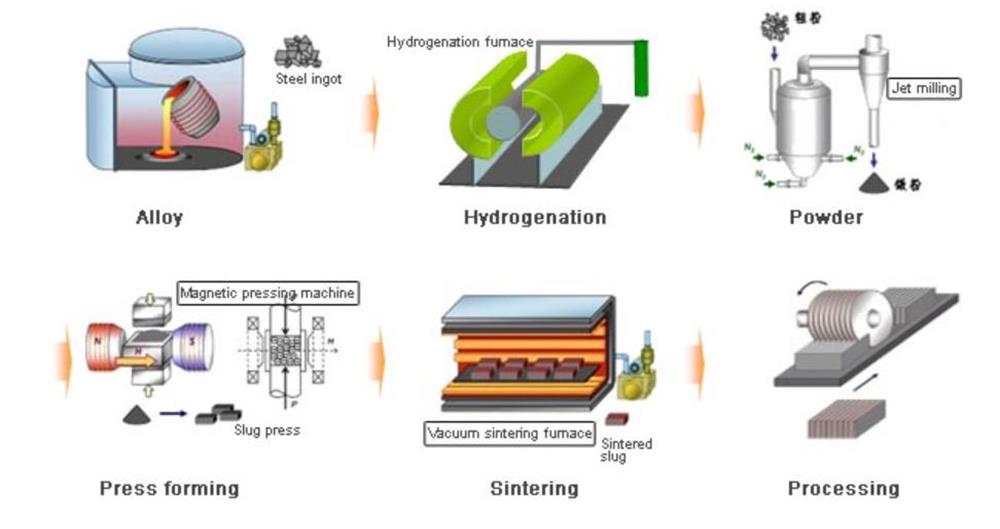

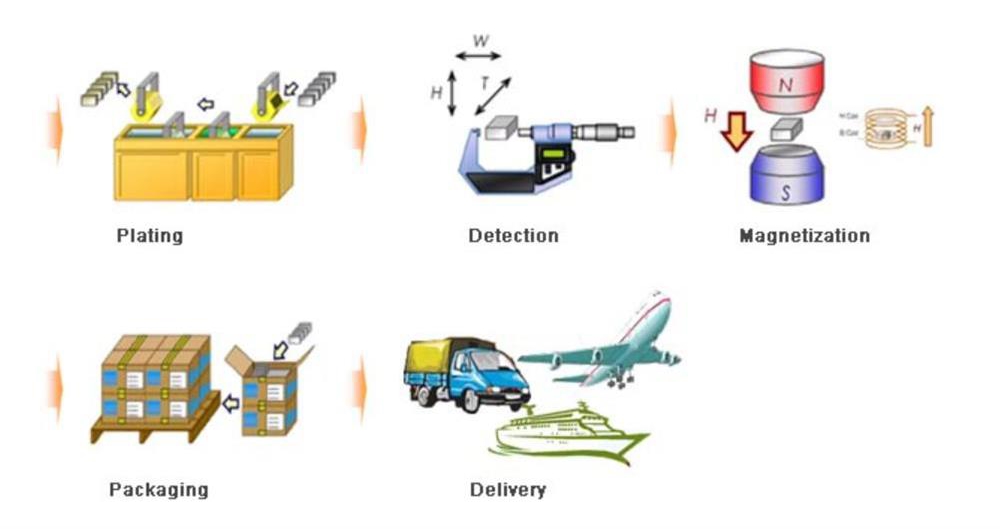

Diagram sruthadh pròiseas

Tolerance Tomhas

| Bathar ann an cumadh ceàrnagach | |||

| Raon Tomhas | Tolerance Tomhas | Co-shìnteachd | Ceart-cheàrnach |

| 0.5≤L≤10 | ±0.03 | ±0.03 | <0.3 |

| 10≤L≤50 | ±0.05 | ±0.05 | |

| L: 50 | ±0.1 | ±0.1 | |

| Bathar cumadh wafer | |||

| Raon Tomhas | Cearcallachd | Tolerance Tomhas | Planeness |

| 1≤D≤5 | ±0.02 | ±0.02 | ±0.02 |

| 5≤D≤25 | ±0.03 | ±0.05 | ±0.02 |

| 25≤D≤50 | ±0.05 | ±0.05 | ±0.03 |

| D: 50 | ±0.05 | ±0.1 | ±0.1 |

| Bathar cumadh fàinne | |||

| Raon Tomhas | Cearcallachd | Tolerance Tomhas | Planeness |

| 1≤d≤3 | ±0.02 | ±0.02 | ±0.02 |

| 3≤d≤5 | ±0.04 | ±0.03 | ±0.02 |

| 5≤d≤15 | ±0.05 | ±0.05 | ±0.03 |

| d 15 | ±0.1 | ±0.05 | ±0.1 |

| Bathar cumadh earrann | ||

| Fulangas geoimeatrach | Raon Tomhas | Tolerance Tomhas |

| Tighead balla | T≤10 | ±0.04 |

| 10<T≤25 | ±0.05 | |

| Fad | L≤10 | ±0.03 |

| 10<L≤25 | ±0.03 | |

| 25<L≤63 | ±0.04 | |

| L 63 | ±0.06 | |

| Fad Chord | W≤63 | ±0.05 |

| W 63 | ±0.06 | |

Tha còrr air 10 bliadhna de eòlas aig Pulong Magnet gus dèiligeadh ri magnets agus toraidhean magnetach!

Co-obrachadh ro-innleachdail le mèinneadair talmhainn tearc Sìona No.1 Chinalco!

Cuir fios thugainnan-diugh no cuir thugainn iarrtas sònraichte agus innis dhuinn dè a tha thu a’ sireadh.